Products:

HG series of rotary dryer is one of the traditional drying equipments and suitable for drying the concentrate by metallic and non-metallic magnetic separation, flotation, gravity concentration, cement clay, coal slime, ore, steel slag, quartz sand, kaolin and peng bentonite etc.

【Heat Source】:Coal, oil, natural gas, timber.

【Application】:Drying the concentrate by metallic and non-metallic magnetic separation,flotation,gravity concentration ,cement clay, coal slime, ore, steel slag, quartz sand, kaolin, peng bentonite, etc.

Advantages:

1. It can change operation parameters according to different material property, the dryer cylinder can form full section material fall which makes the heat exchange more fully.

2. New type feeding and discharging devices completely eradicate the disadvantages of traditional dryer like feeding jams, feeding discontinuously and unevenly returning materials, and reduce the load of dust removal system.

3. Scale plate sealing is used to connect shell and feeding, and discharging device good sealing greatly reduce the shell internal heat loss, thus directly reducing the fuel consumption.

4. Counter-current drying method obtains higher evaporation intensity; Fair current drying method and indirect drying way are suitable for drying temperature sensitive material.

5. New burner satisfies the customers’ demand for saving energy and high efficiency. It can choose diesel oil, heavy oil, natural gas, coal gas etc to be fuel instead of the only choice for coal as fuel in the past.

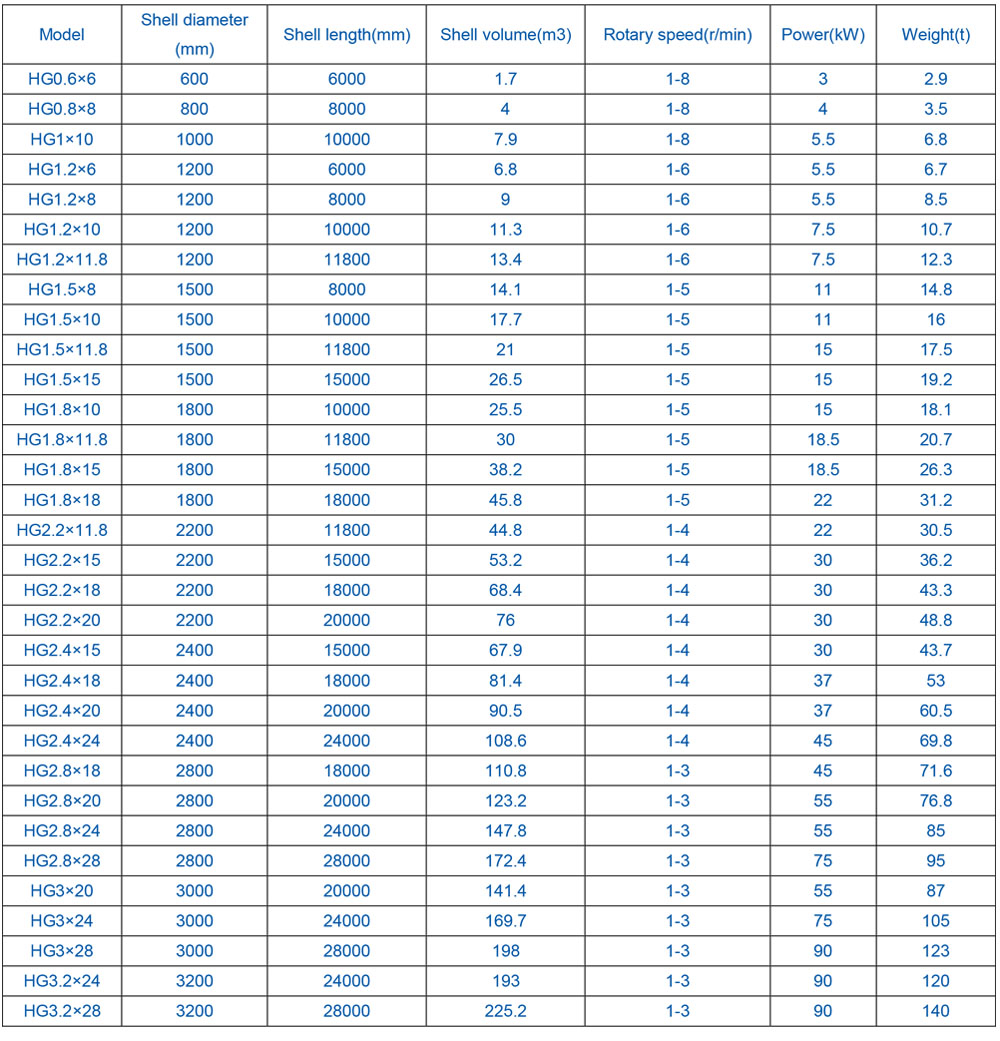

Technical Parameters:

Note: No further notice if the technical parameters change.