Products:

MQ series ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash etc. It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can be adjusted by revising steel balls ratio.

Advantages:

1. When the diameter of ball mill is less than 3200mm, its conventional configuration is using rolling bearing instead of bush sliding bearing energy saving 10% - 20%.

2. When the diameter of ball mill is more than 2700mm, its conventional configuration is using slow driving device for installing liner and maintenance.

3. When the diameter of ball mill is less than 1500mm, its conventional configuration is monolithic large chassis then reduce installation requirements and shorten installation time;

4. When the power of ball mill is less than 110 KW, it uses cage asynchronous motor; When the power of ball mill is more than 110 KW, it uses wire wound asynchronous motor; When the power of ball mill is more than 400 KW, it uses high voltage (6 KV or 10 KV) asynchronous motor or the TDMK series high voltage (6 KV or 10 KV) synchronous motor.

5. Drum Feeder Spiral Feeder and Joint Feeder are available for meeting different working condition.

6. The gear lubrication mode has grease lubrication thin oil lubrication and automatic oil mist lubrication for meeting different working condition.

7. The bearing lubrication has manual and electric grease lubrication pump for automatic lubrication.

8. There are a variety of liner plates types to select. Compared to A series standard type B series energy-saving type can save energy 10% - 20%.

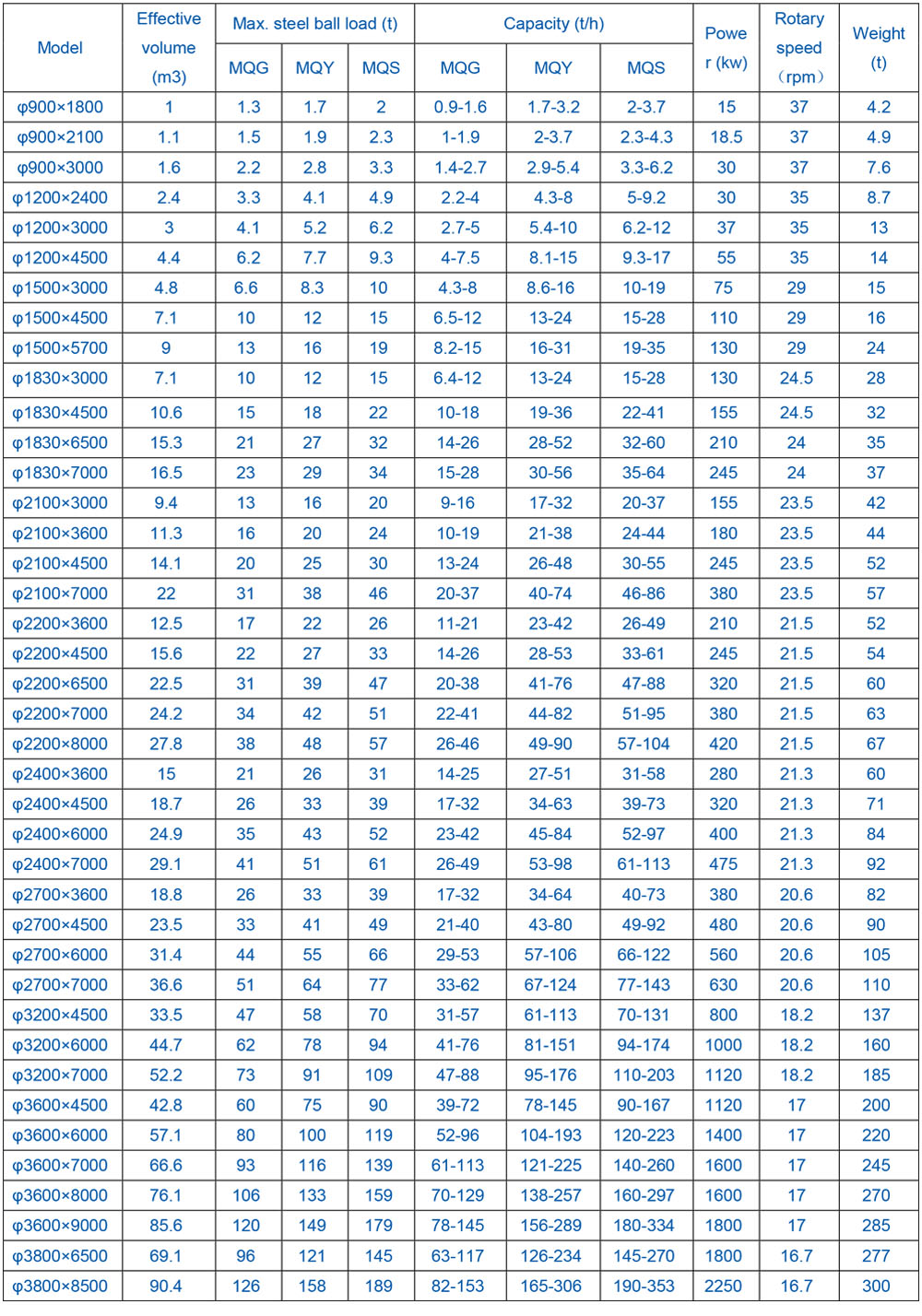

Technical Parameters:

Note:

1. Equipment actual processing capacity, power, weight and technic process has great relationship with equipment configuration, the above data is only for reference.

2. Equipment power changes according to grinding media type, volume load and altitude. The above data is based on wet type grate ball mill, grinding media (steel ball), volume load≤40%, altitude﹤1000m.

3. Shell rotary speed changes according to linear plate type, liner plate thickness and different technic process.